Cutting Labor Costs: Real-World Performance of Seeders in Large-Scale Farmland

Labor shortages and rising wages are reshaping global agriculture. For large farms and contractors, the question is not whether to mechanize, but how to maximize return on equipment while keeping operating costs under control. Among all field operations, seeding determines stand establishment, input efficiency, and ultimately yield. This article analyzes how modern seeding machines reduce labor needs and improve outcomes in large-scale farmland.

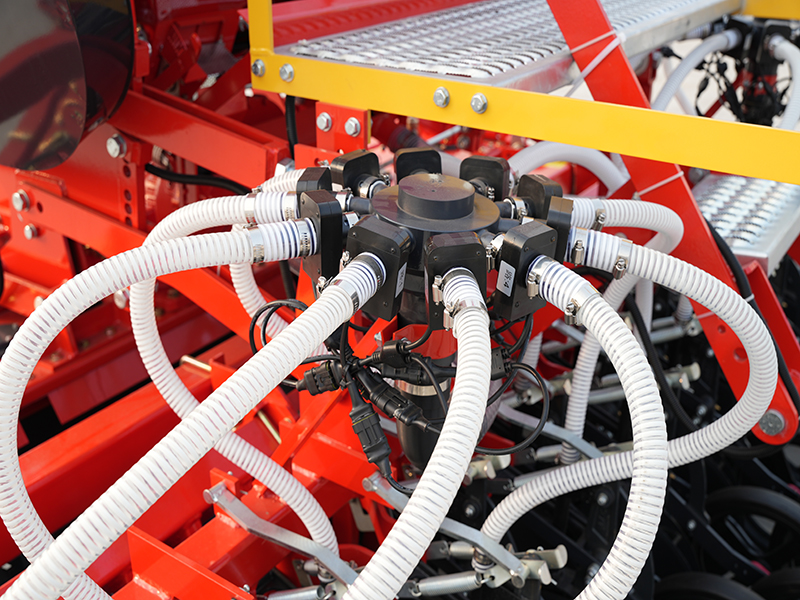

Illustrative placeholder — replace with your field photo or product image to increase trust and conversions.

Contents

How Seeders Cut Labor Cost Performance in Large Fields Economics & ROI Sustainability Benefits Typical Specs Snapshot Conclusion

How Seeding Machines Reduce Labor Costs

Manual seeding is slow, inconsistent, and labor-intensive. Modern planters and seed drills automate placement, depth, and spacing—allowing one operator to cover hundreds of hectares in a tight planting window.

Fewer operators: One tractor + one operator replaces dozens of workers.

Faster fieldwork: High-speed metering and larger working widths shorten planting days.

Lower supervision cost: Digitized settings reduce training and oversight needs.

Real-World Performance in Large-Scale Farmland

1) Precision Planting Improves Emergence

Adjustable row spacing, downforce control, and accurate seed metering deliver uniform depth and spacing. This consistency increases germination rates and establishes even stands for corn, soy, wheat, canola, and more.

2) Adaptable to Crops and Soils

Pneumatic seed drills and row-crop planters handle diverse seeds—from cereals to legumes—across tilled, minimum-till, and no-till fields. Interchangeable seed plates and openers match local conditions.

3) Digital Control & Data

Optional GPS guidance and variable-rate seeding (VRS) reduce overlaps and optimize plant populations by zone. Electronic monitors track skips and doubles, supporting better decisions and traceability.

4) Durability for Heavy Workloads

Robust frames, anti-wear openers, and sealed bearings withstand long hours. Grease intervals and easy-access service points keep machines in the field during narrow planting windows.

Economics & ROI for Export Markets

For growers and contractors, the business case is clear: fewer laborers, shorter planting seasons, and better stands. Savings come from reduced wages, lower overtime, and improved yield stability.

| Factor | Manual Seeding | Modern Seeder |

|---|---|---|

| Labor per 100 ha | 20–40 workers | 1 operator |

| Time to complete | 7–12 days | 1–2 days* |

| Seed placement accuracy | Variable | High (meter-controlled) |

| Overlap / skips | Frequent | Minimal with GPS/VRS |

*Indicative only. Actual field capacity depends on working width, ground speed, headland efficiency, and field shape.

Sustainability Advantages

Precision seeding reduces seed waste, supports lower fertilizer rates per plant, and integrates with conservation tillage. Better stands improve resource-use efficiency and resilience against weather variability.

Typical Specifications Snapshot

Working width: 3–12 m (customizable up to 24 m)

Row spacing: 12.5–75 mm / variable per crop

Metering: mechanical or pneumatic; optional vacuum metering for precision crops

VRS & guidance: optional GPS guidance, section control, variable-rate seeding

Hopper capacity: 200–3,000 L depending on model

Add-ons: fertilizer boxes, micro-granule applicator, no-till openers

Conclusion

For large-scale farming, seeders are the fastest path to lower labor cost, reliable emergence, and higher yields. With export-ready models and global support, we help growers and dealers deploy precision seeding solutions that pay back quickly and perform across diverse crops and climates.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).