Mechanized Farming Solutions: How Rotary Tillers and Seeders Work Together for Higher Efficiency

Introduction

In modern agriculture, farmers face growing pressure to increase yields while cutting costs, conserving resources, and managing labor shortages. Mechanization — when applied intelligently — addresses these challenges. Among the most effective mechanized pairings is the rotary tiller (power tiller/cultivator) combined with a seeder. This article explains how these machines work together, the benefits across crop types and regions, practical purchasing and maintenance guidance, and tips that help exporters and buyers evaluate equipment.

1. What a Rotary Tiller Does

A rotary tiller is engineered to break up compacted soil, mix organic residues evenly, and create a friable seedbed. Unlike conventional moldboard plows that simply invert layers, tillers pulverize and aerate the soil, producing a fine tilth that promotes faster germination and even emergence.

Improves soil structure and aeration

Incorporates residues and organic matter uniformly

Reduces clods for better seed-to-soil contact

Adaptable to multiple soil types (sandy to clay)

2. What a Seeder Brings to the Table

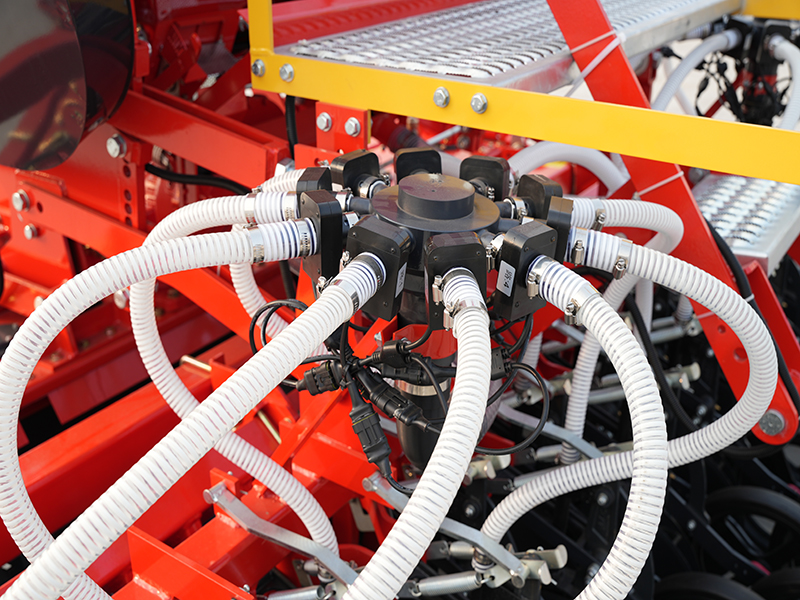

Seeders precisely place seeds at controlled depths and spacings, which has a direct impact on resource efficiency and final yield. Modern seeders offer adjustable metering, row spacing, and depth control; some can handle pelleted seeds, small vegetable seeds, and even precision crops.

Uniform seed distribution and consistent depth

Reduced seed wastage and better germination

Higher crop uniformity improves downstream operations (irrigation, spraying, harvesting)

3. How the Tiller + Seeder Workflow Works

When integrated properly, the tiller prepares an optimal seedbed and the seeder follows immediately to place seeds with minimal delay. There are three common workflow patterns:

Sequential one-pass approach: tiller + seeder mounted or trailed in series to work in one single field pass.

Two-step approach: tiller first, then seeder in a follow-up pass for complex soils or residue-heavy fields.

Integrated units: combined machines that till, seed, and lightly cover seed in a single operation.

The best option depends on crop, soil moisture, residue levels, and machinery availability. One-pass systems offer the biggest labor and fuel savings; two-step approaches can be gentler for heavy-residue or wet soils.

4. Measurable Benefits (What Farmers Actually Gain)

Combining a rotary tiller and seeder produces several measurable advantages:

Time savings: Field operations can be reduced by 30–50% compared to separate plowing and manual sowing.

Labor reduction: Fewer workers are needed; skilled tractor operators can cover much larger areas.

Lower fuel costs: Fewer passes over the field reduce diesel consumption and machine wear.

Higher germination and yield: Uniform seed depth and good seedbed conditions translate into more consistent stands and higher yields per hectare.

Resource efficiency: Precise sowing reduces seed waste and improves fertilizer application efficiency downstream.

5. Applications by Crop & Region

The tiller + seeder combination is versatile. Below are common matches by crop type:

Grains (wheat, barley, corn): Large-area sowing benefits from mounted or trailed multi-row seeders.

Rice systems: In upland rice and seedbed preparation for transplanted rice, tillers condition soil for nursery beds and seeders can be used in dry-seeded rice.

Vegetables (carrot, onion, lettuce): Precision seeders increase uniformity and harvest quality.

Legumes and oilseeds (soybean, peanut): Accurate spacing improves root development and harvest efficiency.

Across Africa, Asia, South America and Eastern Europe, compact tiller-seeder systems enable smallholders and co-ops to mechanize effectively without the high cost of large tractors and implements.

6. Choosing the Right Combination: Practical Buyer Tips

International buyers should evaluate machines with careful attention to local conditions. Key purchase considerations:

Soil type & moisture: Heavy clay and wet fields may need staggered passes or special tine designs.

Tractor horsepower compatibility: Match implements to the local tractor fleet — underpowered tractors reduce efficiency and increase wear.

Seeding requirements: Check metering systems for seed size, seeding rate range, and compatibility with coated/pelleted seeds.

Spare parts & service: Choose exporters who provide spares and clear documentation (manuals, exploded diagrams) and can support international shipping and customs paperwork.

Warranty & training: Look for suppliers who provide reasonable warranties and optional field training for operators.

7. Maintenance & Lifetime Cost Considerations

Total cost of ownership depends heavily on maintenance. Basic guidelines to reduce downtime and extend life:

Clean implements after use to prevent rust and residue build-up.

Lubricate bearings, chains, and PTO couplings per manufacturer schedule.

Keep a small stock of common wear parts: blades/tines, seed metering wheels, drive belts, bearings.

Train local technicians in simple repairs and part replacement to avoid long downtime from shipping delays.

8. Exporter Perspective: What International Buyers Should Expect

Reputable exporters — particularly many manufacturers in China — can offer competitive pricing plus customization. For international procurement:

Certifications: Ask for ISO or CE documentation when required by your market.

Custom adjustments: Row spacing, hitch types, and seeder metering can often be tailored to your crops.

Logistics: Confirm packaging, weight/volume, and shipping options (FCL/LCL) and who handles customs clearance.

After-sales support: A clear spare parts list, quick-response contacts, and availability of local agents are critical.

9. Case Example (Illustrative)

A cooperative with 120 hectares of mixed grain in Eastern Europe upgraded from hand sowing to a mounted rotary tiller + 6-row seeder. Results in one season:

Field preparation and sowing time reduced by ~45%.

Seed usage reduced by 12% due to improved metering and reduced overlap.

First-year yield improvement of 8–11% due to better stand uniformity.

While results vary by region and management, this kind of improvement is common where mechanization replaces manual or semi-mechanized workflows.

10. Frequently Asked Questions (Short)

Q: Can any tractor run a rotary tiller + seeder?

A: Check the PTO power and recommended horsepower range. Compact tillers and seeders work with small tractors; large multi-row seeders need higher horsepower units.

Q: Are there integrated machines that till and seed in one pass?

A: Yes — integrated seeders with light covering units exist and are ideal for dry, low-residue fields.

Q: How important is after-sales service?

A: Extremely. Spare parts, technical manuals, and local support minimize downtime and preserve ROI.

Conclusion & Next Steps

The combination of a rotary tiller and seeder is a proven mechanization pathway for farms aiming to increase efficiency, reduce costs, and improve yields. Whether you manage a small family farm, a commercial vegetable operation, or a large grain enterprise, selecting the right tiller + seeder pairing tailored to your soils, crops, and tractor capacity will deliver measurable benefits.

If you are evaluating equipment for export or purchase, prioritize: compatibility, spare parts availability, warranty terms, and seller reliability. Those factors will determine long-term value more than the initial purchase price alone.

Call to Action

If you represent a farm, distributor, or co-op and want tailored recommendations (model selection, tractor compatibility checks, or a spare-parts quote), please contact our sales team. We specialize in export-ready tillers and seeders with customizable options to suit diverse international conditions.

Tip: Prepare the following before contacting suppliers — field size (ha), soil type, typical residue, preferred crops, and tractor HP available. This will help get an accurate recommendation quickly.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).