The Ultimate Guide to Troubleshooting Hydraulic System Failures in Agricultural Tractors: Solve Common Issues Effectively

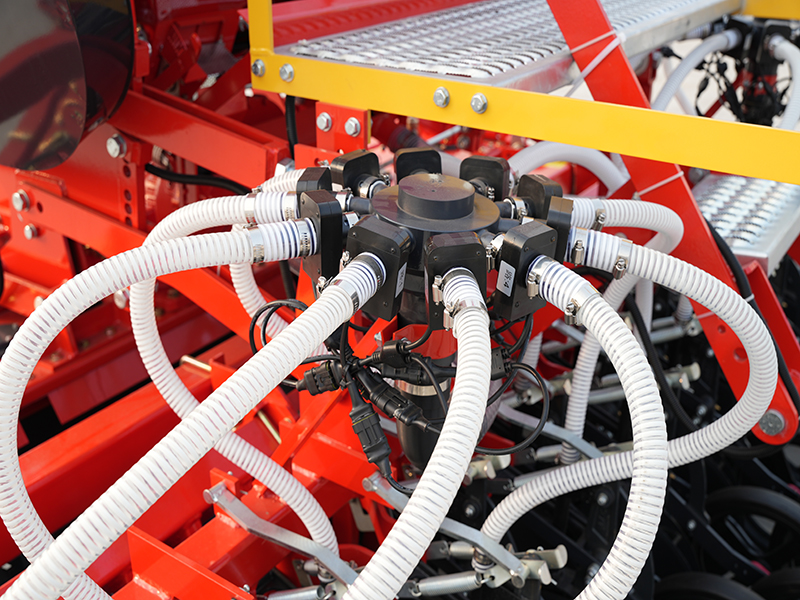

Agricultural tractors are essential machines in modern farming, and their hydraulic systems are responsible for transmitting power, operating tools, and maintaining machine efficiency. However, over time or due to improper operation, hydraulic systems can experience failures that reduce the tractor's performance and even lead to downtime. Understanding common hydraulic system failures and mastering effective troubleshooting methods not only extends the tractor’s lifespan but also boosts work efficiency and reduces maintenance costs.

This article will provide a detailed guide on common hydraulic system failures in agricultural tractors, troubleshooting steps, and maintenance tips to help you quickly identify and resolve issues.

Common Hydraulic System Failures in Agricultural Tractors

Hydraulic system failures typically manifest as abnormal operation, pressure anomalies, or system leaks. Below are some of the most common types of failures:

1.Hydraulic Oil Leaks

Hydraulic oil leaks are one of the most common hydraulic system failures. Leaks can result in insufficient oil pressure, reduced power, or even system failure. Common leak points include cylinder seals, hose connections, and oil pumps.

2.Hydraulic Oil Contamination

Over time, hydraulic oil may become contaminated, causing increased friction within the system, reduced efficiency, and even damage to components. Contaminants can come from air, water, or foreign particles.

3.Pump Failures

If the hydraulic oil pump is malfunctioning, it may fail to provide a consistent pressure, affecting the operation of the entire hydraulic system. Pump failures are often indicated by increased noise, fluctuating oil pressure, or system unresponsiveness.

4.Abnormal Pressure

Both high and low hydraulic pressure can lead to improper tractor operation. Excessively high pressure increases the load on components, while low pressure may fail to provide enough power for the task at hand.

5.Slow or Sticking Hydraulic Cylinders

Hydraulic cylinders that are sticking or moving slowly are usually caused by poor sealing or insufficient hydraulic oil. These issues affect operational precision and may even render the equipment unusable.

Troubleshooting Steps for Hydraulic System Failures

Step 1: Check Hydraulic Oil Levels and Quality

Start by checking the oil level. If the level is low, add more hydraulic oil. If the oil level is normal, assess the oil’s quality. If the oil is contaminated, discolored, or viscous, it may need to be replaced.

Step 2: Inspect the Hydraulic Pump

A malfunctioning hydraulic oil pump is often responsible for insufficient pressure or system failure. Start the tractor and listen for any unusual noises coming from the pump. Use a pressure gauge to check if the pump’s output pressure is within the specified range.

Step 3: Locate and Repair Leaks

Examine all hose connections, seals, and pipes for signs of oil leakage. Common leak points include hose joints, cylinder seals, and the pump. If leaks are found, tighten the joints or replace the seals.

Step 4: Check Hydraulic Cylinders

Inspect the hydraulic cylinders for smooth operation. If the cylinders are sticking or moving slowly, check their seals and ensure there are no contaminants inside. Cleaning or replacing components may be necessary.

Step 5: Inspect Hydraulic Control Valves

Hydraulic control valves regulate oil flow and pressure. If these valves malfunction or become clogged with debris, the cylinders may not operate correctly. Inspect the valves to ensure they are clean and function smoothly.

Maintenance and Care Tips for Hydraulic Systems

1.Regularly Replace Hydraulic Oil

Over time, hydraulic oil can become contaminated or degrade, which may affect system performance. Regularly change the hydraulic oil, using the manufacturer-recommended type, and clean the oil reservoir to remove any debris.

2.Monitor Hydraulic Oil Temperature

If the oil temperature gets too high, it can accelerate the degradation of the oil. Regularly monitor the oil temperature to ensure it stays within the recommended range. Consider installing a temperature control device if necessary.

3.Keep the Hydraulic System Clean

Any contamination in the hydraulic system can significantly impact its efficiency. Regularly clean the oil reservoir, pipes, and filters to maintain cleanliness and ensure optimal performance.

4.Inspect Seals Regularly

Aging seals are a common cause of hydraulic system failure. Regularly check the seals on cylinders and hoses, replacing them when they show signs of wear.

5.Avoid Overloading the System

Operating the tractor with an overloaded hydraulic system can lead to overheating or excessive wear. Avoid working the system beyond its recommended capacity, especially in high-load operations, and maintain a reasonable work intensity.

Conclusion

The hydraulic system is a critical part of agricultural tractors, and ensuring its proper operation is essential for efficient farming. Regularly inspecting and maintaining the hydraulic system, identifying issues early, and troubleshooting problems will reduce downtime and extend the life of the tractor. We hope the troubleshooting methods and maintenance tips provided in this article will help you better care for and maintain your tractor’s hydraulic system, ultimately improving work efficiency.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).