Next-Generation Cultivator Debuts: Enhanced Deep-Tillage Performance for Thorough Soil Loosening

Next-Generation Cultivator Debuts: Enhanced Deep-Tillage Performance for Thorough Soil Loosening

As global agriculture seeks higher productivity with lower inputs, tillage equipment plays a central role in creating healthy seedbeds and restoring soil porosity. Today we introduce a next-generation deep-tillage cultivator engineered to deliver improved penetration, consistent working depth, and more thorough soil loosening — attributes that directly support better root development, water infiltration, and crop performance.

Why Deep Tillage Still Matters

Deep tillage breaks compacted layers (plowpan), increases soil aeration, and promotes water movement into the profile. For many cropping systems — from cereal grains to vegetable rotations — this process improves root penetration and nutrient uptake. However, inconsistent depth control, excessive draft, and poor shank design can reduce effectiveness and raise operating costs. The new cultivator is designed to overcome those limitations with proven mechanical and hydraulic upgrades.

Core Performance Enhancements

Key upgrades at a glance:

Hydraulic depth control for precise, consistent subsoil engagement across varying field conditions.

Reinforced frame and gusseting to withstand heavy loads and deliver longer service life.

Optimized shank geometry with wear-resistant tips to reduce draft and maintain penetration.

Interchangeable coulter and crumbler options to match soil types and desired seedbed finish.

Modular sections—simple to configure for different row widths, tractors, and container shipping.

Technical Highlights — What’s Under the Hood

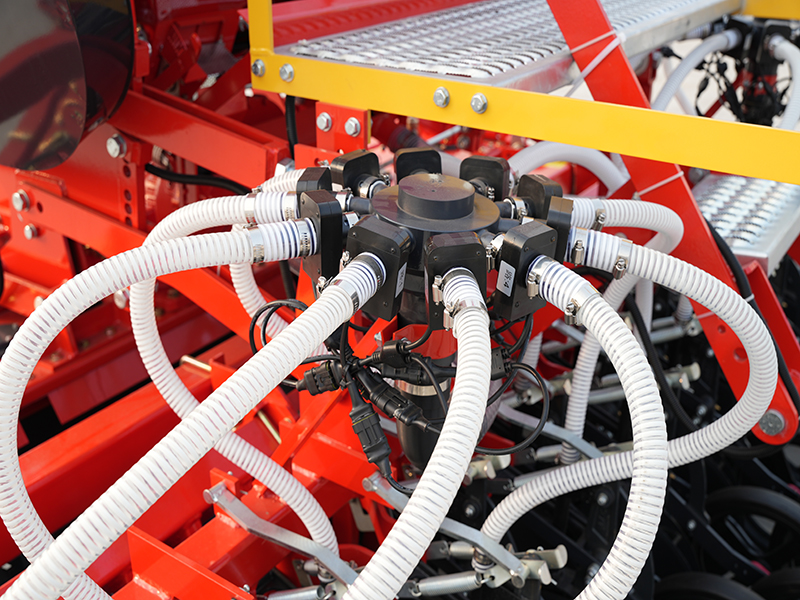

The cultivator pairs well-proven mechanical design with field-oriented features. Robust materials — high-tensile steel for the main beam and hardened spring or replaceable shank tips — reduce downtime and maintenance. Hydraulic depth control uses a simple valve-and-cylinder arrangement with a manual override for fast field adjustments. Optional shock attenuation protects the structure when encountering stones or unexpected obstructions.

Improved Fuel & Tractor Efficiency

Engineered shank geometry and reduced draft translate into lower tractor drawbar pull for a given depth — which means less fuel consumption and reduced wear on tractors. For large-scale operations where hours in the field equate to significant cost, these efficiency gains quickly add up and improve the cultivator’s total cost of ownership.

Soil Health & Sustainability Benefits

Thoughtful tillage preserves structure while delivering the agronomic benefits. By loosening compacted horizons and improving infiltration, this cultivator supports reduced runoff and better water storage in the root zone. Durable parts reduce replacements and waste, and the improved efficiency reduces fuel-related emissions — an important consideration for sustainability-minded buyers and export markets with environmental compliance requirements.

Versatile Use Cases

The machine is suitable for a wide range of agricultural tasks:

Primary deep cultivation before sowing major cereal crops.

Periodic soil aeration in rotational farming systems.

Pasture renovation and improvement of grazing land.

Pre-plant bed preparation for high-value horticultural crops.

Export Readiness & Compliance

Designed by an exporter for global customers, the cultivator accommodates container dimensions and is available in modular kits to reduce freight costs. Manufacturing follows ISO-aligned quality processes, and documentation packages include operator manuals, spare-parts lists, and CE/other region-specific compliance options where applicable. Spare parts support and clear service instructions help overseas dealers and customers minimize downtime.

Maintenance & Serviceability

Service considerations were prioritized in the design phase: easily accessible grease points, replaceable shank tips, and bolted wear plates simplify routine service. Optional maintenance kits and illustrated service guides further speed up repairs in the field, making the machine attractive to contractors and farms with limited workshop access.

Selecting the Right Model for Your Farm

Choosing the correct cultivator configuration depends on soil type, tractor horsepower, and the desired working width. Lighter soils typically favor narrower shanks and higher speeds, while heavy clay requires stronger shanks, lower speeds, and possibly a pre-cutting coulter. Our product range includes different tine spacing, shank options, and mounting styles (3-point, trailed) to match diverse operational needs.

Commercial Opportunity & Market Positioning

For distributors and dealers, this cultivator represents an opportunity to offer an efficient, durable tillage solution that addresses both productivity and sustainability demands. Positioning points for sales and marketing include lower operating costs, robust build, modular shipping, and local serviceability — all of which resonate across export markets.

Conclusion — Practical Innovation for Modern Farming

The next-generation cultivator redefines deep tillage by delivering precise depth control, reduced draft, and a durable, service-friendly design. Whether deployed on large grain farms, vegetable operations, or pasture renovation projects, this machine helps growers improve soil conditions and long-term productivity. For exporters and global buyers, its modularity and compliance-ready design make it a competitive choice in international markets.

Interested in specifications or a customized configuraton for your market? Contact our export team for datasheets, shipping options, and localized compliance documentation.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).