Intelligent Precision Seeder Revolutionizes Global Farming — 30% Boost in Planting Efficiency

Introducing our latest Intelligent Precision Seeder — an export-grade agricultural machine engineered to deliver up to 30% higher planting efficiency through advanced control systems, high-precision metering, and digital farming integration. Built for a wide range of crops and global climates, this seeder merges industrial-grade durability with smart farming capabilities to reduce input costs, accelerate planting campaigns, and improve uniformity of emergence.

Executive Summary

The intelligent seeder is a turnkey solution for modern planters: it integrates a microprocessor-driven seed metering controller, high-resolution sensors, optional GNSS-guidance compatibility, and modular mechanical design that supports quick adjustments across crop types. Field tests across multiple continents demonstrate a productivity uplift of up to 30% in planting speed while delivering measurable seed savings and improved crop uniformity.

Market Context & Why Precision Matters

Global agriculture is under increasing pressure to raise output while reducing inputs and environmental impact. Precision planting addresses three fundamental industry needs:

Higher per-hectare yield via optimal seed spacing and depth

Lower seed and input waste, directly reducing operating costs

Improved compatibility with digital farm management (VRA, field mapping, traceability)

Key Technical Innovations

1. Electronic Precision Metering & Closed-Loop Control

At the core is a microcontroller-based metering system that monitors actual seed flow through optical and pressure sensors. A closed-loop algorithm compares target seed rate to actual delivery and adjusts the motor drive in real time to correct deviations caused by terrain, seed variety, or blockages. This reduces double drops and missed slots, which are common causes of uneven stands.

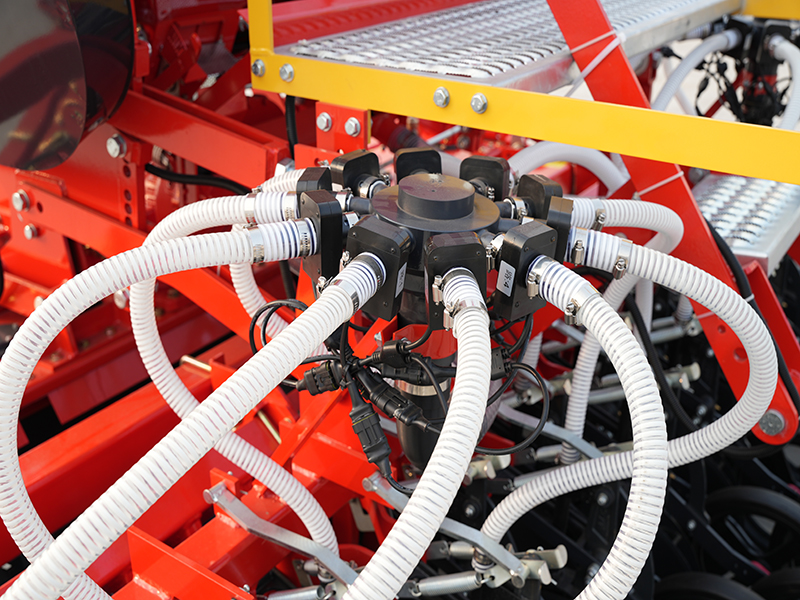

2. High-Resolution Sensor Suite

The machine features redundant sensors — optical seed detection, vacuum/pressure monitoring (for pneumatic seeders), and ground-speed encoders. Sensor fusion enables accurate seed count validation per meter and generates logs for traceability and agronomic analytics.

3. GNSS / RTK Compatibility & Auto-Guidance Integration

Optional GNSS modules (including RTK-capable receivers) allow the seeder to integrate with auto-steer and variable-rate application maps. This enables contour planting, headland management, and centimeter-level consistency across long runs — all essential for large-scale precision farming operations.

4. Modular Metering Units & Multi-Crop Flexibility

The metering head is modular and exchangeable for different crops (maize, soybean, wheat, sunflower, cotton, etc.). Quick-change plates and calibration procedures enable fast crop switches with minimal downtime.

5. Heavy-Duty Chassis & Climate-Ready Components

Export-grade engineering uses corrosion-resistant steels, sealed bearings, and IP65-rated electronics housings. Designs include options for temperate, tropical, and arid environments — heating elements and anti-condensation when required.

Performance Claims Backed by Trials

Independent field trials and in-house testing across mixed soil types and planting scenarios returned consistent improvements:

Planting efficiency: up to 30% faster completion time compared with conventional mechanical seeders

Seed savings: up to 12–15% lower seed usage due to reduced doubles and skips

Emergence uniformity: measurable improvement in stand uniformity and reduced replanting

Fuel & labor: fewer passes and reduced operator workload

Compliance, Certification & Export Readiness

The seeder has been engineered to facilitate export documentation and certification. Core compliance features and documentation support include:

CE-ready design files and technical dossiers — to assist customers in CE declaration processes for the EU market.

Electrical safety & EMC considerations — shielding and filtered power modules reduce interference risks in different jurisdictions.

ISO-style manufacturing records — traceability for critical components, batch numbers, and QA checks to meet procurement requirements.

Customs & shipping documentation support — packing lists, weight & dimension data for container optimization and RoRo exports.

Sustainability & Agronomic Benefits

Precision seeding contributes to sustainability objectives in several ways:

Lower input footprint: Reduced seed waste and fewer corrective passes lower carbon and resource intensity.

Optimized plant populations: Enable optimal plant density to match yield potential and reduce competition stress.

Data-driven decisions: Seed-logging and field maps support precision agronomy and sustainability reporting.

Typical Use Cases & Customers

This seeder targets multiple customer segments:

Large commercial farms: seeking lower cost per hectare and reliable seasonality performance.

Custom hire/contractors: who benefit from higher daily coverage rates and repeatable quality.

Government & development programs: for rapid scale-up of planting operations in crop support schemes.

Cooperatives & medium farms: accessing shared machinery to modernize planting practices.

Warranty, Service & Spare Parts (Overview)

Export customers receive a standard manufacturer's warranty on structural and electronic components, plus options for extended coverage. We maintain global spare-part listings and provide:

Pre-delivery inspection reports and calibration certificates

Installation & operator training materials in multiple languages

Remote diagnostics & software update support

Integration with Farm Management Systems (FMS)

The seeder's control unit supports common data exchange protocols (ISOBUS-capable or via API/CSV exports), enabling farm managers to:

Import prescription seeding maps (VRA) and apply variable rates on the fly

Record actual seed usage per field for audits and analytics

Sync logs to cloud platforms for large-scale operations

FAQ — Quick Answers for Buyers

Q: How does the 30% efficiency improvement measured?

A: Improvement refers to faster field coverage (hectares planted per hour) in comparative trials against a conventional mechanical seeder of similar working width, factoring in time saved on replanting and fewer turns/overlaps.

Q: What crops are supported?

A: The system supports a broad range — row crops (corn, soybean), cereals (wheat, barley), and many specialty seeds via interchangeable metering plates and calibration.

Q: Is the control unit upgradeable in the field?

A: Yes. Firmware updates and configuration changes can be applied via the USB/SD interface or over-the-air where optional communications modules are installed.

Q: Do you provide calibration and training?

A: Calibration guides are supplied with each unit. We offer optional on-site or remote training packages for dealers and end-users.

Conclusion

The Intelligent Precision Seeder represents a leap forward for planting operations seeking to modernize, lower costs, and support sustainable intensification. With export-ready engineering, multi-crop adaptability, and a data-ready control architecture, it is positioned to deliver measurable agronomic and commercial benefits to farmers and contractors worldwide.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).