How to Choose the Right Lawn Mower for Mountain Orchards? 3 Best-Selling Models for 2025

Maintaining grass and understory growth in a mountain orchard is very different from mowing a flat lawn. Slopes change traction and balance, tree rows restrict turning space, and seasonal weather can turn soil from dust to slick mud within days. The right mower reduces labor hours, improves fruit quality by controlling competing vegetation, and lowers accident risk. This guide explains the specific challenges in hillside orchards, compares mower types, and offers a clear selection framework—followed by three best‑selling model recommendations for 2025.

1) What Makes Mountain Orchards Difficult to Mow?

Steep, variable slopes: Side‑hill mowing shifts the center of gravity and raises rollover risk. Grades can change quickly between terraces and natural contours.

Uneven ground and obstacles: Roots, rocks, irrigation lines, trunk guards, trellis posts, and fallen branches demand precise maneuvering and durable decks.

Dense, fibrous vegetation: Tall fescues and brushy weeds require high torque, reinforced blades, and multi‑stage cutting heights to avoid clogging.

Microclimate effects: Morning dew and shade keep ground wet on north‑facing rows, while south‑facing slopes dry fast—changing traction within the same block.

Row spacing and turning radius: Narrow alleys between trees limit deck width and demand responsive steering to prevent bark damage.

2) Mower Types for Hillside Orchards: Pros & Cons

A. Walk‑Behind Brush Cutters (Wheeled)

Heavy‑duty walk‑behinds use high‑torque engines and steel decks to slice tall grass and saplings. Their low center of gravity and slower travel speed make them stable on slopes up to moderate gradients.

Pros: Excellent stability, precise trimming near trunks, lower purchase cost.

Cons: Lower productivity on large acreages; operator fatigue over long shifts.

B. Ride‑On Mowers (4WD / Diff‑Lock)

Purpose‑built hillside ride‑ons feature 4WD, differential locks, and wide wheelbases for traction and stability. They cover more area per hour and can carry wider decks while maintaining balance.

Pros: High productivity, operator comfort, consistent cut quality.

Cons: Higher cost; require trained operators and careful slope limits.

C. Remote‑Control Track Mowers

Tracked, radio‑controlled units keep operators off dangerous slopes. Their low ground pressure and aggressive cutters manage thick brush on very steep grades where ride‑ons shouldn’t go.

Pros: Safest option on extreme slopes; excellent traction; minimal soil compaction.

Cons: Highest initial cost; slower transport between blocks; battery or fuel logistics.

3) A Simple Framework to Choose the Right Mower

Map your slopes: Identify maximum side‑hill and uphill/downhill grades in each block. Note wet zones, ruts, and rocky patches that affect traction.

Measure row spacing and headlands: This determines safe deck width and turning radius. Narrow rows favor compact decks (42–54in); wider rows can take 60–72in.

Define vegetation load: Tall, fibrous grasses and brush require higher torque, heavy blades, and staged cutting heights (e.g., first pass high, second pass low).

Choose drive & tires: 4WD or diff‑lock improves hillside grip; ag‑tread or turf‑saver tires protect soil while maintaining traction.

Prioritize safety & ergonomics: Parking brake, blade clutch, clear slope rating, low‑vibration controls, and good visibility reduce fatigue and incidents.

Plan service access: Filters, belts, and grease points should be reachable without removing major panels—saving hours across the season.

4) Three Best‑Selling Models (2025)

A. Model X‑7000 — All‑Terrain Powerhouse

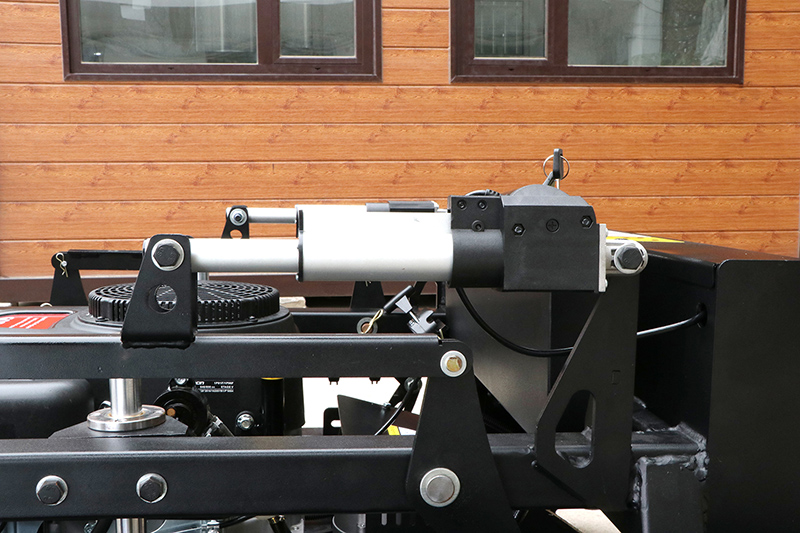

Built for demanding slopes with a robust frame and low center of gravity. The drivetrain’s torquey gearing pairs with all‑terrain tires to keep traction on loose gravel and damp soil.

24HP high‑performance engine

4WD with differential lock

Cutting height: 1–6in (25–150mm)

Deck width: 60in (1524mm)

Steel deck with brush guards

Ergonomic seat and controls

Service‑friendly filter & belt access

Recommended slope: moderate–steep

Best use: large hillside blocks

B. Model V‑Trek 4500 — Compact & Agile

A nimble platform for narrow rows and mixed terrain. Offers confident handling with a tight turning radius and enough torque to keep pace with seasonal growth.

15HP efficient engine

Deck width: 48in (1219mm)

Six cutting heights

Compact chassis for tight headlands

Ergonomic controls, low vibration

Easy belt and blade access

Best use: small–medium orchards

C. Model G‑Drive 5000 — Heavy‑Duty Workhorse

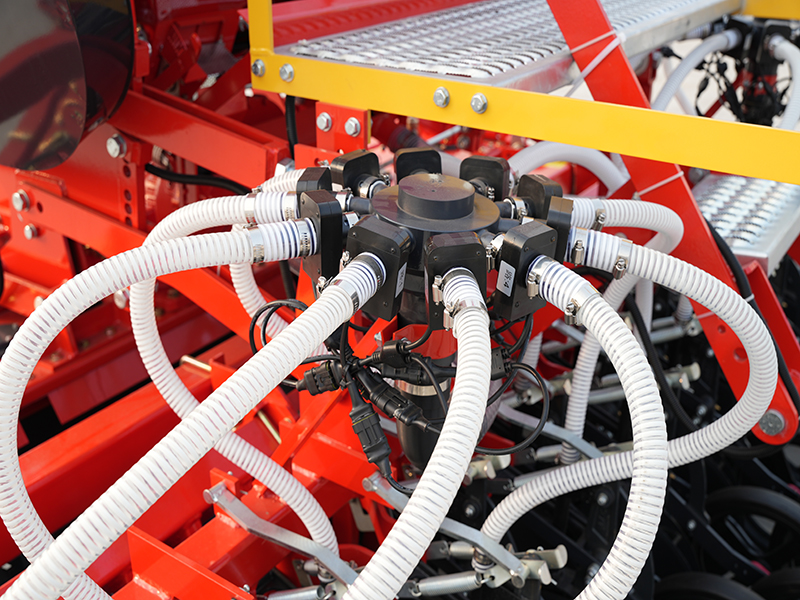

A commercial‑grade solution for extreme slopes and dense brush. Hydraulic drive keeps power steady, while the reinforced 72‑inch deck maximizes throughput over large acreages.

30HP high‑torque engine

Deck width: 72in (1829mm)

4WD, aggressive anti‑slip tires

Reinforced frame, continuous‑duty cooling

Service ports for fast maintenance

Recommended slope: steep–extreme

Best use: large commercial hillside orchards

5) Operation on Slopes: Techniques & Safety

Slope work is where most incidents occur. Adopt strict procedures, post signage, and train operators before the busy season.

Respect slope ratings: Never exceed the machine’s published limits.

Mow up/down on steep grades, and only side‑hill within rated angles.

Use low range and steady throttle to avoid abrupt weight transfer.

Walk rows first: Remove rocks, branches, and check irrigation lines.

Plan escape routes and mark hazards at row ends.

Stop if traction breaks, lower deck, reduce throttle, and retreat safely.

6) Efficient Mowing Patterns for Tree Rows

Pattern selection reduces soil compaction and saves time:

Contour passes: Follow slope contours to maintain traction.

Double‑height approach: First pass high to clear bulk, second pass low for finish.

Headland buffers: Leave a wider turning zone at row ends to protect trunks.

Under‑canopy trimming: Use walk‑behinds around guards where ride‑ons can’t fit.

7) Seasonal Maintenance Checklist

Pre‑Season

Change oil and filters; inspect fuel lines

Sharpen/replace blades; torque check fasteners

Grease bearings; verify belt condition

In‑Season

Clean deck daily to prevent buildup

Check tire pressure and tread wear

Monitor belts, clutches, and cooling intake

Post‑Season

Stabilize fuel or drain; fog engine if needed

Replace worn blades, belts, tires

Clean, touch‑up paint, store under cover

8) Cost of Ownership: Buying vs. Running

Upfront price is only one part of the decision. Over five years, fuel efficiency, blade wear, belt life, tire replacement, and downtime often outweigh initial savings. Machines with easier service access and durable decks may cost a little more but typically deliver a lower cost per hectare mown.

Fuel & blades: Dense grass increases consumption and wear—plan inventory.

Tires: Hillside traction tires wear faster on gravel headlands.

Unplanned downtime: Quick‑access filters and sealed bearings reduce stoppages.

Resale value: Well‑maintained commercial units hold value and upgrade easily.

9) Quick FAQs

Q: How wide should the deck be between tree rows?

A: Match deck width to row spacing minus a safe clearance on both sides; 48–60in works well for most blocks.

Q: Is 4WD necessary?

A: On mixed or steep slopes, 4WD or diff‑lock dramatically improves stability and productivity.

Q: Can I mow when the ground is wet?

A: Avoid saturated soil to reduce rutting and sliding. If unavoidable, reduce deck height, slow down, and mow up/down.

10) Conclusion

For mountain orchards, the right mower blends torque, traction, and maneuverability with practical service access and clear slope ratings. Walk‑behind brush cutters excel around trunks and guards, ride‑on 4WD units deliver productivity on moderate to steep slopes, and remote‑control track mowers create a safety margin on extreme grades. Among current best‑sellers, the X‑7000, V‑Trek4500, and G‑Drive5000 cover the full range of orchard scenarios—from tight headlands to expansive hillside blocks. Match machine to slope, rows, and vegetation load, and you’ll cut faster, safer, and more cost‑effectively throughout the season.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).