We recommend most of the options for you.

They are equipped with state-of-the-art engines to ensure optimal performance.

Learn more

Tractor + loader (excavator + bulldozer) can choose whether to be equipped with a cab

Learn more

Precision sowing, the sowing amount adopts a seeder with stepless speed adjustment

Learn more

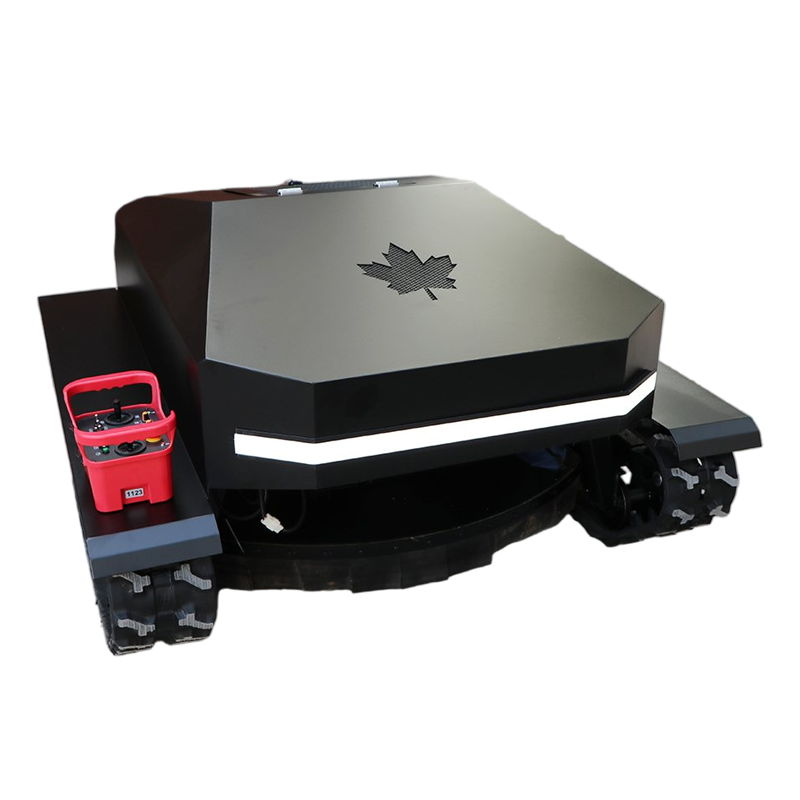

Hybrid electric, fully remote-controlled mower equipped with multiple sensors

Learn more

We can provide you with more choices.