Energy-Saving and Efficiency: Future Trends of Electric Lawn Mowers

As a Chinese manufacturer of electric lawn mowers serving global markets, we have observed a clear shift in customer demand from North America, Europe, Oceania, and the Middle East toward “higher efficiency, lower energy consumption, smarter operation, and easier maintenance.” This article explores the future trends of electric lawn mowers, covering battery technology, power systems, automation, lightweight structures, sustainability, and fleet management. It is optimized for Google SEO and user readability.

1. Battery Technology Upgrades: From NMC to LFP and Solid-State Batteries

LFP (Lithium Iron Phosphate) for safer, longer life cycles: Compared to NMC, LFP batteries offer superior thermal stability and lifespan, making them ideal for high-frequency commercial use.

Fast charging & battery-swapping ecosystems: 30–60 min fast charge and swap-ready designs greatly enhance continuous operation.

Smart BMS: Advanced SOH (State of Health) and SOC (State of Charge) monitoring, combined with cloud analytics, improves battery longevity and predictive maintenance.

Solid-state batteries: In the long term, solid-state batteries will deliver higher energy density and enhanced safety, becoming the premium segment trend.

Customer benefits: Lower total cost of ownership (TCO), higher uptime, and cross-device battery platform sharing.

2. Power Systems: Brushless Motors + FOC Vector Control

Brushless DC motors (BLDC) are replacing brushed motors: 10–30% higher efficiency, longer service life, and lower maintenance.

FOC (Field-Oriented Control) with smart torque distribution: Adjusts output based on grass density, terrain slope, and blade load to achieve “on-demand power”, reducing energy peaks.

Dual-motor or independent hub drive (especially in robotic and high-end walk-behind mowers) improves stability on complex terrain.

3. Smart & Autonomous: Moving from “Self-Propelled” to “Self-Deciding”

Robotic mowers becoming mainstream:

RTK high-precision positioning + vision/lidar sensors eliminate the need for boundary wires, making deployment faster and easier.

AI-powered path planning: Optimizes cutting schedules, paths, and speed based on grass growth patterns and historical data.

App & Cloud Management:

Homeowners: Remote start, scheduling, path visualization, OTA firmware updates.

Commercial users: Fleet grouping, field maps, task dispatch, energy statistics, maintenance alerts.

Predictive maintenance (PdM): Uses motor current, vibration, and temperature data to detect potential failures (e.g., blade imbalance, bearing wear) and reduce unplanned downtime.

4. Low Noise & Vibration: Ideal for Residential and Night Operations

Lower dB(A) levels: Optimized motor acoustics and blade aerodynamics make these mowers ideal for schools, hospitals, and neighborhoods.

Anti-vibration structure: Floating decks, vibration isolation, and aerodynamic blade designs reduce operator fatigue and noise pollution.

5. Lightweight & Modular Designs: Efficiency and Serviceability

Lightweight materials: A mix of high-strength steel, aluminum alloy, and engineering plastics improves cutting area per unit of energy.

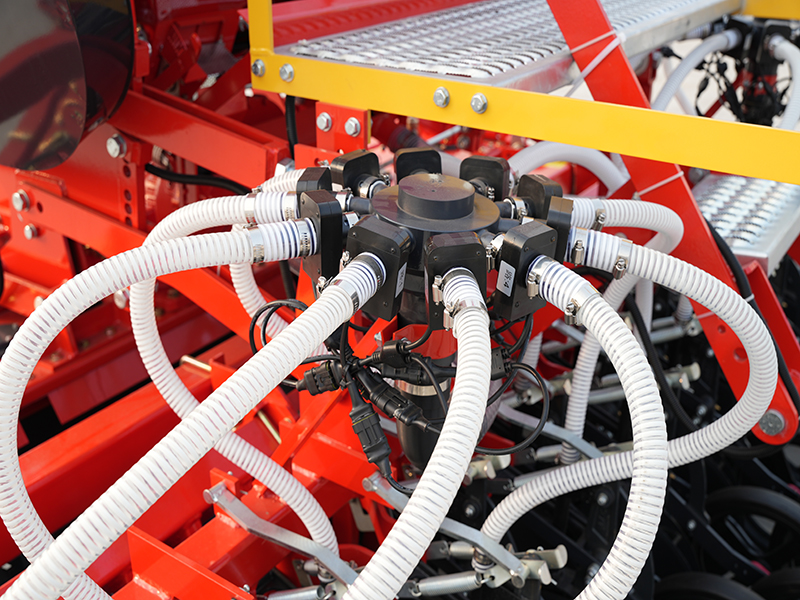

Modular platforming:

Powertrain modules (motor/controller/battery compatibility).

Deck modules & cutting height mechanisms.

Unified wiring and communication interfaces to simplify spare parts management and reduce maintenance costs.

6. Sustainability & Life Cycle (LCA) Design

Higher recyclability: Recyclable plastics, blades, and tires.

Battery recycling & second-life use: Old batteries repurposed for stationary energy storage.

Eco-friendly logistics: Foldable or stackable designs reduce shipping and warehousing costs.

7. Safety & Compliance: Global Certification Readiness

Electrical safety & EMC: CE, UKCA, UL/ETL, CSA, etc.

IP protection: IPX4–IPX5 for outdoor use, with robotic mowers moving toward higher waterproof standards.

Functional safety: Emergency blade stop, tilt/lift sensors, boundary detection, and object avoidance.

Noise & vibration compliance: Meeting EU/US limits for urban use.

We offer certification-ready designs and third-party testing for all target markets.

8. Fleet Management for Commercial Use: Data-Driven ROI

Cloud-based fleet platforms: Real-time equipment location, task progress, energy reports, and health monitoring.

API & data integration: Seamless integration with property management or landscaping platforms.

Service-based business models: Pay-per-area, pay-per-hour, or pay-per-job pricing improves operational efficiency and reduces labor costs.

9. User Experience: Interaction & Maintenance-Friendly

One-touch height adjustment + digital control panels: Precise height settings and energy modes.

Tool-free maintenance: Quick-release blades, pull-out filters, hot-swappable batteries.

Ergonomics & safety: Adjustable handles, vibration damping grips, keyless start, NFC/password anti-theft systems.

10. Future Product Roadmap (OEM/ODM Options)

Entry-level residential series: Compact, quiet, and affordable for small yards.

Premium residential/semi-pro models: Brushless motors + LFP batteries + smart apps + fast charge/swappable batteries.

Commercial series: Large battery packs, modular decks, higher IP ratings, and fleet integration.

Fully autonomous robotic series: RTK + AI vision, OTA updates, field mapping, predictive maintenance.

Cross-platform battery ecosystems: Shared battery packs for mowers, chainsaws, leaf blowers, and other garden tools.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).