Detailed explanation of tractor chassis: a solid foundation for efficient agricultural operations

In the field of agricultural machinery, tractors are undoubtedly one of the most core and commonly used equipment. It is not only a "jack of all trades" for mechanized farming, but also a symbol of efficient production in modern agriculture. However, under the conspicuous technical halo of engines, hydraulic systems, electronic control units, etc., there is an often overlooked but extremely important part-the tractor chassis. It is like the skeleton of the human body, supporting the structure, power transmission and stable operation of the entire machine.

This article will comprehensively explain the basic concepts, composition structure, technical types, adaptation suggestions and daily maintenance of the chassis to help users deeply understand the technical value and selection significance of this key component.

1. What is the chassis? Why is it so important?

The tractor chassis is the intermediate structural system connecting the engine and the ground, and is an indispensable core part of the whole machine composition. It undertakes three core functions:

Load-bearing function: bear the weight of the whole machine and the additional load of agricultural implements;

Power transmission: transmit the power output of the engine to the wheels or tracks through speed change, differential and other links;

Control guarantee: support steering, braking, and shock absorption systems to achieve safe and stable operation.

The quality of the chassis directly affects the tractor's traction, passing ability, fuel economy and overall durability.

2. Detailed explanation of the five components of the chassis system

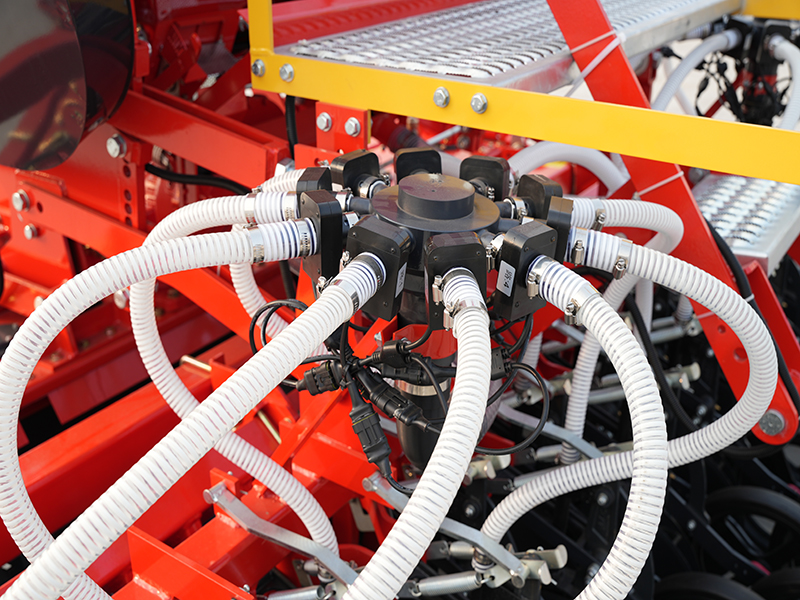

(1). Transmission system: the "conveyor belt" of power

The task of the transmission system is to transmit the power of the engine to the drive wheels in a controllable manner, mainly including:

Clutch: Controls whether the power is transmitted, which is the key to starting and shifting.

Gearbox: Adjusts the driving speed and torque output, and common forms include mechanical, hydraulic, power shifting, etc.

Central drive shaft: Transmits the output of the gearbox to the differential, and undertakes high torque tasks.

Differential and final drive: Ensure the speed difference between the inner and outer wheels when turning, and improve driving efficiency.

Most modern medium and large tractors use synchronizer speed change or electro-hydraulic control speed change, which makes gear shifting smoother and adapts to different operating scenarios.

(2). Walking system: "feet" for support and movement

The tractor contacts the ground through wheels or tracks to achieve walking and operation advancement.

Wheeled chassis: mainly pneumatic or solid tires, fast driving speed, flexible control, suitable for transportation and dryland operations.

Tracked chassis: rubber or steel tracks, large ground contact area, strong passability, suitable for paddy fields, mountains, and soft areas.

Four-wheel drive system: an increasingly popular configuration that can effectively enhance traction and slope stability.

In addition, some high-end models are also equipped with an adjustable wheelbase system and a high ground clearance structure, which is convenient for working in the field of row-spacing crops.

(3). Steering system: a guarantee of precise control

Mechanical steering: simple structure, low cost, mostly used for small tractors;

Hydraulic power steering: easy to operate, quick response, and has now become the mainstream;

Electronic steering system (EPS): a high-end configuration that can automatically adjust the steering force or realize automatic navigation linkage.

Modern agriculture has continuously improved its requirements for precision operations, and the accuracy and stability of the steering system directly affect the operating efficiency and labor burden.

(4). Braking system: the "gatekeeper" of safe operation

The agricultural operation environment is complex, the tractor has a large load and strong inertia, and the reliability of the braking system is particularly critical.

Drum brake: suitable for medium and low speed heavy load, closed structure, good dustproof;

Disc brake: good braking effect, fast heat dissipation, often used in high-end models;

Wet multi-disc brake: widely used in large four-wheel drive tractors, wear-resistant and long life;

Dual-circuit hydraulic brake + handbrake system: enhances operational safety, suitable for long-term operation and slope operation.

Some large imported models also integrate technologies such as power-assisted braking and hill start control system to further improve control safety.

(5). Frame structure: the backbone of rigidity and load-bearing

The frame is the basic platform connecting key assemblies such as the engine, gearbox, suspension, and axle. Common structures include:

Integral cast frame: strong rigidity and good stability;

Semi-suspension frame: lightweight design, suitable for medium-sized machines;

Modular frame structure: easy to disassemble and repair, suitable for multi-purpose models.

Modern frame design pays more attention to the balance between strength and weight to improve fuel efficiency and maneuverability.

3. Chassis selection suggestions for different operation scenarios

| Type of assignment | Recommended chassis structure | Features |

|---|---|---|

| Dryland farming | Wheel chassis + four-wheel drive | Flexible, fast and fuel-efficient |

| Paddy field operations | Tracked chassis | No car sinking, strong adhesion |

| Mountainous hills | Short wheelbase 4WD chassis | Small turning radius and strong climbing ability |

| Orchard operations | Narrow track wheeled chassis | Large ground clearance, no damage to crops |

| Reinforced transmission chassis | Reinforced transmission base | Strong bearing capacity and high stability |

According to different agronomic needs and geographical environments, choosing a suitable chassis structure can effectively improve the applicability and economy of the tractor.

4. Daily maintenance guide for chassis: the key to extending service life

Check whether the transmission parts are worn or leaking, especially the gearbox and differential;

Keep the steering system flexible, add steering fluid or replace oil seals regularly;

Clean up chassis attachments to prevent mud and straw from affecting the work of tracks or tires;

Tighten the connecting bolts regularly to avoid loosening due to vibration;

Tire/track inspection: timely replace aging and flat tires, and maintain proper tire pressure;

Brake system inspection: check the brake pads and brake oil status at least once a quarter.

Good maintenance can not only avoid sudden failures, but also extend the overall service life of the tractor and reduce operating costs.

5. Conclusion: Invisible key, visible value

Although the tractor chassis is often regarded as a "basic configuration", it carries the core function of the whole machine operation. With the continuous deepening of agricultural intelligence and mechanization, chassis technology is also constantly upgrading. From the traditional mechanical structure to today's integrated, electronically controlled, and lightweight design, the chassis system is gradually transforming into a "technological skeleton".

When buying a tractor, you should not only look at horsepower and brand, but also pay attention to the rationality and adaptability of the chassis structure. Only when the foundation is laid can the operation be efficient and stable.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).