Tractor power analysis, which tractor is more suitable for you

Tractors are indispensable key equipment in modern agricultural production. The quality of their power systems directly affects the operating efficiency, economy and the mechanization level of various agronomic links. Especially in the context of my country's agricultural structural transformation and the accelerated development of large-scale operations, users are paying more and more attention to the power performance of tractors. This article combines the technical characteristics of current mainstream models to systematically analyze tractor power from the aspects of power source, transmission system, power distribution, operation matching and development trend, aiming to provide technical reference and selection guidance for practitioners.

1. Power source analysis

The power source of tractors is mainly diesel engines, which have the characteristics of high fuel economy, high torque at low speed and strong reliability. Diesel engines have good stability under different loads, and are especially suitable for low-speed and high-load operation requirements in agricultural operations.

(1). Power level classification

According to the scale and purpose of operation, tractor engine power is usually divided into the following levels:

| Power Range (HP) | Type | Applicable scenarios |

|---|---|---|

| 20~50HP | Small tractor | Orchards, greenhouses, hilly areas |

| 50~120HP | Medium tractor | Ordinary dry land, paddy fields, livestock breeding areas, etc. |

| 120~300HP | Large tractor | Large farms, deep tillage, combined land preparation, sowing, etc. |

| 300HP or more | Extra large tractor | Suitable for plain field operations or heavy-duty operations |

(2). Power performance indicators

The selection of tractor engines should comprehensively consider the following core parameters:

Rated power (kW/HP): The maximum power that the engine can sustainably output at rated speed is the basic indicator for measuring the overall power capacity of the tractor.

Maximum torque and speed range: Determine the endurance of the tractor under high load and low speed conditions.

Fuel economy and emission standards: Engines that meet the National IV/National V emission standards have become mainstream, taking into account both environmental protection and efficiency.

Optimal RPM: refers to the speed range with optimal fuel consumption and stable output, which affects the operating cost.

2. Powertrain Analysis

The core of the power system is not only the engine itself, but also how it efficiently transmits power to the drive wheels and operating parts. The transmission system is the key to power utilization efficiency.

(1). Transmission Type

(a) Mechanical Transmission (MT)

Traditional structure, gear meshing transmission, high efficiency and low maintenance cost, but high labor intensity when shifting frequently. Suitable for standard operations such as farming and transportation.

(b) Synchromesh Transmission (Synchromesh)

Adding a synchronization device to the mechanical structure to improve the smoothness of gear shifting is a common configuration for mid-range models.

(c) Power Shift

With multiple gears, gear shifting can be performed without interrupting power, adapting to complex terrain or heavy load operations, and reducing operator fatigue.

(d) Continuously Variable Transmission (CVT)

High-end configuration, smooth and continuous speed and power adjustment, precise power output, effectively improving fuel economy and operation quality, suitable for high-efficiency, large-area farming scenarios.

(2). Drive mode and differential control

2WD (rear drive): simple structure, suitable for flat terrain areas.

4WD (four-wheel drive): improves traction, climbing ability and passability in slippery areas, and is standard for modern medium and large tractors.

Electronic control differential lock: improves off-road capabilities, suitable for muddy or slope operations, and prevents wheel slippage.

3. Power distribution structure

The power output of the tractor is not all used for driving, but also includes power diversion of multiple key systems:

(1). Driving system

Mainly responsible for traction operations, such as tilling land, transportation, etc. Most of the power is transmitted to the drive wheels through the transmission system to ensure thrust and grip.

(2). Power output shaft (PTO)

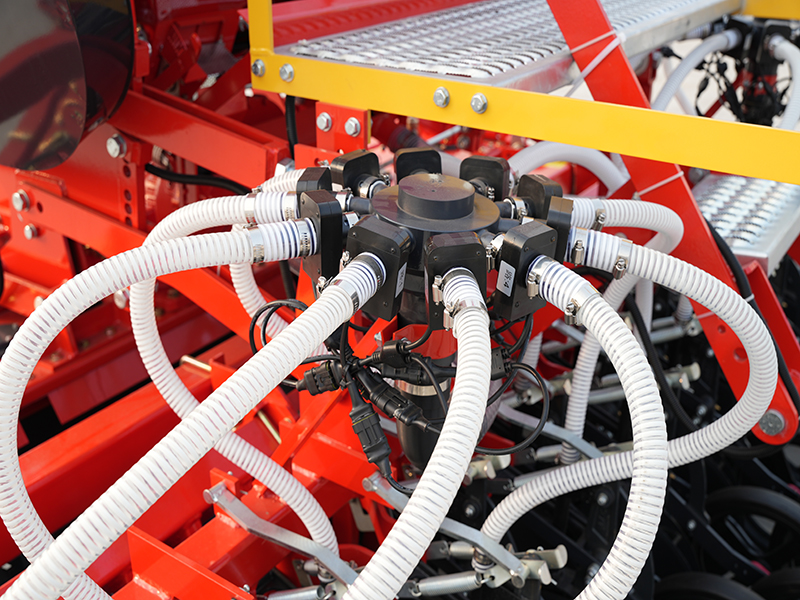

Used to drive agricultural implements (such as rotary tillers, seed drills, balers, etc.), the output forms include standard speeds such as 540 rpm and 1000 rpm. Some high-end models also have variable speed PTO or independent PTO control systems to improve operational flexibility.

(3). Hydraulic system

Controls the lifting and lowering of agricultural implements, steering wheel steering and counterweight adjustment, etc. The selection and layout of the hydraulic pump directly affect the operational response speed and the ability of multiple implements to work together.

4. Power performance under different working conditions

(1). Tillage and land preparation operations

Requires low speed and high torque, suitable for high-displacement, high-compression ratio engines and low-gear traction mode, and requires precise power distribution to avoid slipping and idling.

(2). Sowing and fertilization operations

Needs stable operation at medium speed, and stable PTO output is particularly critical. Power shift or CVT models are preferred to maintain constant speed operation.

(3). Harvesting and baling operations

The core is the continuous and efficient output of PTO and precise hydraulic control. The engine and hydraulic system need to be highly matched to ensure the synchronous operation of the header and the baling system.

(4). Transportation operations

It requires both high speed and fuel economy. The mechanical or power shift transmission performs well. The high-speed gear design (such as 16+8, 24+12 gears) can effectively improve transportation efficiency.

5. Development trends and technological innovations

(1). Power electronic control technology upgrade

Technologies such as electronically controlled high-pressure common rail system, variable injection timing (VVT), and intelligent turbocharging continue to improve engine efficiency and response speed while meeting environmental regulations.

(2). Hybrid power and electric drive

Some new tractors have begun to use electric drive systems, which are especially suitable for precision agriculture and environmentally sensitive areas (such as vegetable bases). Low noise and zero emissions have become new advantages.

(3). Intelligent power management

The engine, transmission, and hydraulic system are managed in a linked manner through the on-board control system to achieve optimal power distribution, automatic fuel adjustment, and remote monitoring.

6. Conclusion

The power system of a tractor is the core embodiment of its comprehensive performance. Reasonable power matching not only affects the operating efficiency, but also affects the operating cost and the life of the machinery. With the development of intelligent and green agriculture, the power structure of tractors is transforming from "strong power" to "intelligent allocation, energy saving and high efficiency". In the process of serving users and promoting products, if Wang Zhanfeng Abu can combine the actual characteristics of the user's plot, operating needs and economic ability, and scientifically select from the perspective of the power system, it will surely bring customers higher-value agricultural machinery solutions.

5. Get Your Personalized Solution Now

→ Call the selection hotline: (also supports accessory customization inquiries).